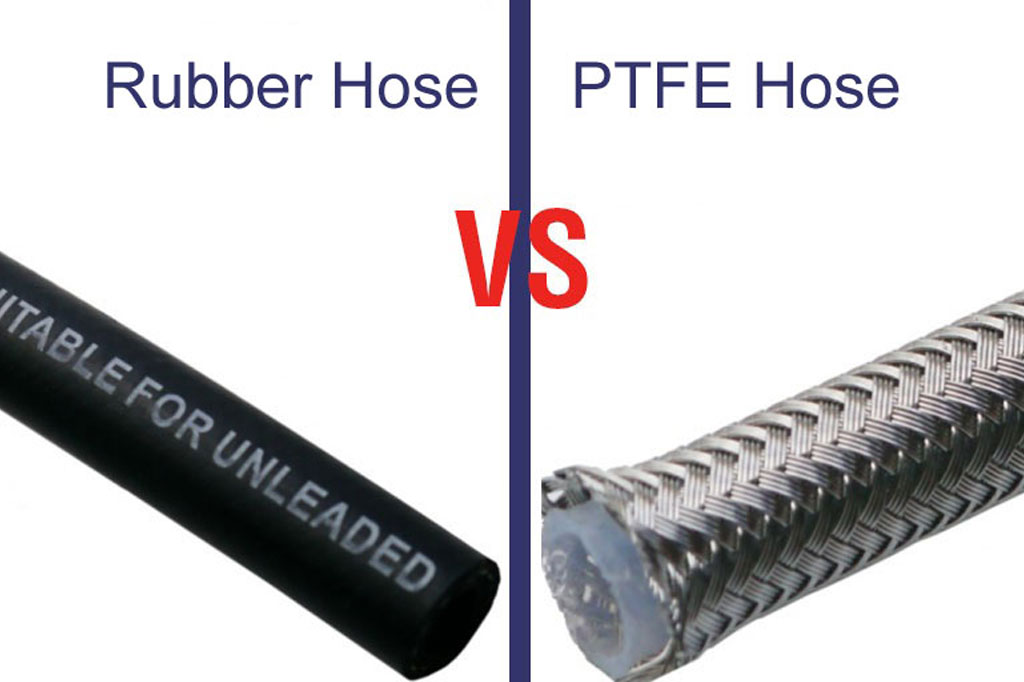

In the field of fuel transfer systems, selecting the appropriate material hose is crucial to ensure efficiency, durability, and safety. Two popular materials for fuel hoses are PTFE (Polytetrafluoroethylene) and rubber.

In this article, we will delve into the characteristics of both PTFE and rubber hoses to help you make an informed choice for your specific fuel transfer system needs.

PTFE Hose and Rubber Hose Comparison Chart

Feature | PTFE Hose | Rubber Hose |

Material Composition | PTFE, a synthetic fluoropolymer | Natural or synthetic rubber |

Temperature Range | Excellent high and low temperature resistance (-70°C to +260°C) | Varies depending on the type of rubber (-40°C to +150°C typical for standard rubber) |

Chemical Resistance | Excellent chemical resistance to a wide range of fluids, including acids, bases, and solvents | Varies; may be affected by specific chemicals and concentrations |

Pressure Rating | High pressure capabilities | Varies depending on the type and construction |

Permeability | Low permeability, excellent for applications requiring fluid purity | Have higher permeability compared to PTFE, which can be a concern in certain applications |

Abrasion Resistance | Less prone to abrasion damage | Can be susceptible to abrasion |

UV Resistance | Excellent resistance to UV rays | May degrade over time with exposure to UV radiation |

Electrical Conductivity | Non-conductive | Conductive or non-conductive, depending on the type of rubber used |

Application | Often used in critical applications such as chemical transfer, pharmaceuticals, and high-performance automotive systems | Commonly used in a variety of applications including air, water, oil, and hydraulic systems |

For more details of these two fuel hoses, please keep reading…

PTFE Hose

PTFE hoses, commonly known as Teflon hoses, have gained popularity in various industrial applications, including fuel transfer systems. Here are some of the notable advantages and disadvantages of PTFE hoses:

|

|

PTFE Hose Pros:

- Chemical Resistance: PTFE hoses exhibit exceptional resistance to a wide range of chemicals, making them suitable for handling different types of fuels without degradation.

- Temperature Tolerance: PTFE hoses can withstand extreme temperatures, ranging from very low to very high, without compromising their structural integrity.

- Smooth Surface: PTFE hoses have a smooth inner surface, reducing friction and minimizing the chances of clogs or blockages in the fuel transfer system.

- Non-Permeable: PTFE hoses are non-permeable, preventing fuel from leaching through the hose walls.

PTFE Hose Cons:

- Flexibility: Compared to rubber hoses, PTFE hoses may be less flexible, potentially making installation in tight spaces more challenging.

- Cost: PTFE hoses tend to be more expensive than rubber hoses, which could be a deciding factor for budget-conscious consumers.

Rubber Hose

Rubber hoses have been a traditional choice for fuel transfer systems, and they continue to be widely used. Here are the pros and cons associated with rubber hoses:

|

|

Rubber Hose Pros:

- Flexibility: Rubber hoses are highly flexible, making them easy to install in various configurations, including tight spaces.

- Cost-Effective: Rubber hoses are generally more cost-effective than PTFE hoses, making them an attractive option for those working within budget constraints.

- Shock Absorption: Rubber hoses provide a level of shock absorption, which can be beneficial in applications where vibrations or movements are common.

- Variety: Rubber hoses come in a variety of types, including synthetic rubber options, catering to specific fuel types and application requirements.

Rubber Hose Cons:

- Chemical Compatibility: While rubber hoses are suitable for many fuels, they may not offer the same level of chemical resistance as PTFE hoses, making them less ideal for handling certain aggressive substances.

- Permeability: Rubber hoses may be permeable to some extent, allowing fuel to seep through the hose walls over time.

Conclusion

PTFE hoses are excellent for chemical resistance and extreme temperature conditions, but they come at a higher cost. On the other hand, rubber hoses offer flexibility and cost-effectiveness but may lack the chemical resistance of PTFE hoses. Carefully assessing your requirements and considering the pros and cons of each option will guide you towards making an informed decision that aligns with your fuel transfer system goals.

Are there any PTFE hoses that can be connected to a metal tube using standard hose clamps or do they all need special end fittings?