Virgin PTFE Gaskets

Made from 100% pure, unreinforced PTFE material without any fillers or additives. Our virgin PTFE gaskets are commonly used in applications where chemical resistance and non-stick properties are crucial.

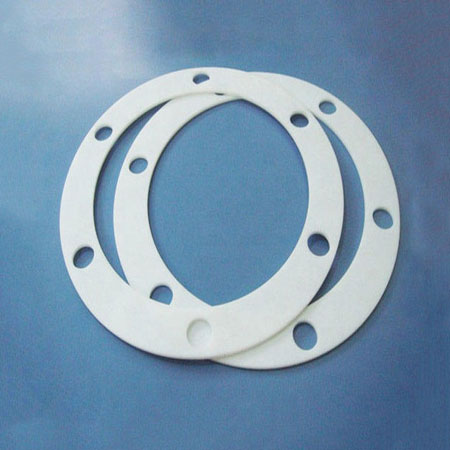

PTFE Flange Gasket

This is a specifically designed PTFE gasket for flanged connections. PTFE flange gaskets are available in various shapes, sizes and thicknesses to match different flange configurations, including full-face gaskets and ring gaskets.

PTFE Rope Gasket

This type of gasket is made by extruding PTFE into a rope-like form, which can then be cut into desired lengths for applications. They are often braided or twisted to enhance their flexibility and compressibility, typically white or off-white in color.

PTFE Tri Clamp Gasket

The gasket is placed between the two ferrules and compressed using the clamp, creating a secure and leak-free seal. PTFE tri clamp gaskets are specifically designed to fit Tri Clamp fittings and provide a reliable seal in sanitary and hygienic applications.

ePTFE Gasket

ePTFE gaskets have excellent sealing properties, as the expanded structure allows for better conformity and adaptation to irregular sealing surfaces. The porous nature of ePTFE also enhances its ability to fill micro-leaks and provide a tight seal.

Reinforced PTFE Gaskets

Virgin PTFE gaskets have relatively low mechanical strength and creep resistance, making it susceptible to deformation under load and cold flow over time. To overcome these limitations, we also provide reinforced PTFE gaskets, which incorporate reinforcing materials to enhance their mechanical properties.

PTFE Envelope Gasket

It consists of a PTFE envelope or sheath that encloses a filler material, which can provide the gasket with resilience and flexibility, allowing it to adapt to flange surfaces and create a reliable seal. Common filler materials include non-asbestos fibers, ePTFE, or rubber. The design of the PTFE envelope gasket makes it can be used in applications involving aggressive chemicals, high temperatures, and pressures.

PTFE Spiral Wound Gasket

PTFE spiral wound gasket is typically constructed using a combination of PTFE filler material and a metal winding strip, such as stainless steel. The metal winding provides structural support and strength, while the PTFE filler material ensures excellent chemical resistance and low friction. It can effectively seal against a wide range of media, including acids, alkalis, solvents, gases, and various fluids.

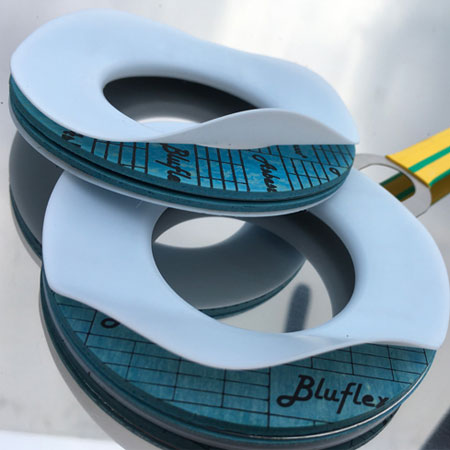

PTFE Bonded EPDM Gasket

It is constructed by bonding a layer of PTFE to the sides of an EPDM rubber gasket. The PTFE layer acts as a chemical barrier, providing protection against aggressive media (acids, bases, and organic solvents), while the EPDM base provides the necessary elasticity and sealing properties. The combination of EPDM and PTFE creates a gasket that can withstand a wider range of chemical environments.

Get In Touch With Us

FAQs of PTFE Gaskets

How are your PTFE gaskets manufactured?

Our PTFE gaskets are produced through a process known as compression molding. PTFE resin is compressed between heated molds under high pressure. The gasket is then cut to the required shape and size.

Can your PTFE gaskets be customized for specific applications?

Yes, our PTFE gaskets can be custom-made to meet specific application requirements, including size, shape, and thickness, based on the needs of the customer.

Do your PTFE gaskets require any special handling during installation?

PTFE gaskets are relatively easy to install. However, you should not overtighten the gaskets, as they may deform and lose sealing properties. Follow our recommendations for proper installation.

Do you have stock samples? And how to get them?

Yes, we have a large inventory of PTFE gaskets in our warehouse. Free samples only take 5~7 days leading time for a quick quality check.

What are your payment terms?

- For sample orders, Paypal or T/T 100% as a deposit.

- For bulk orders, we request 30% by T/T in advance, the balance to be paid before shipment.