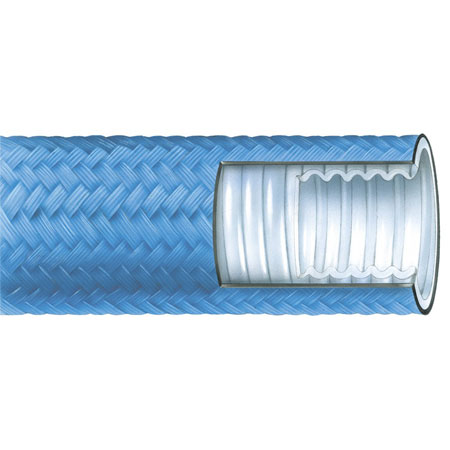

PTFE Braided Hose Construction

The inner layer is a PTFE hose or corrugated hose. The outer braiding layer is typically made of stainless steel or other materials with high tensile strength, such as Nylon, Polypropylene and Kevlar.

Stainless Steel Braided

The stainless steel braiding provides high strength and mechanical protection to the hose, making it suitable for applications where the hose may be subjected to high pressures, abrasion, or physical impact. PTFE stainless steel braided hoses are commonly used in applications such as hydraulic systems, fuel lines, brake lines, oil lines, and high-pressure pneumatic systems.

Nylon Braided

Nylon braiding offers good flexibility, a lightweight design and resistance to moisture absorption and corrosion. It also provides some level of abrasion resistance. PTFE Nylon braided hoses are suitable for applications where flexibility and lightweight construction are important, such as automotive fuel lines, coolant systems, and low-pressure pneumatic systems.

Polypropylene Braided

Polypropylene braiding provides good chemical resistance and is generally resistant to mildew and rot. It also offers moderate flexibility. PTFE Polypropylene braided hoses are commonly used in applications where chemical resistance is crucial, such as chemical transfer, food processing, pharmaceutical industries and other corrosive media handling.

PTFE Stainless Steel Braided Hose Data Sheet

Inner Hose Size (inch) | Inner Hose Size: ID*OD (mm) | Braided Hose ID (mm) | Braided Hose OD (mm) | Wall Thickness (mm) | Working Pressure (kg) | Burst Pressure (kg) | Minimum Bending Radius (mm) |

1/8 | 3.4*5.4 | 3.0~3.4 | 5.8~6.2 | 1 | 280 | 840 | 40 |

3/16 | 5*6.5 | 4.6~5.0 | 7.1~7.7 | 0.75 | 227 | 680 | 50 |

1/4 | 6.5*8.5 | 6.1~6.5 | 9.1~9.7 | 1 | 210 | 630 | 75 |

3/8 | 10*12 | 9.5~10 | 12.6~13.2 | 1 | 163 | 490 | 125 |

1/2 | 13.2*15.2 | 12.7~13.2 | 15.6~16.2 | 1 | 140 | 420 | 165 |

3/4 | 19.5*22 | 19~19.5 | 22.9~23.5 | 1.25 | 83 | 250 | 230 |

1 | 25.3*28.3 | 24.8~25.3 | 28.9~29.5 | 1.5 | 67 | 200 | 300 |

Get In Touch With Us

FAQs of PTFE Braided Hose

What types of PTFE braided hose you can provide?

We can provide PTFE braided hoses with smooth bores or convoluted (corrugated) bores. PTFE braided hoses with smooth bores are ideal for applications requiring high flow rates and easy cleaning, while convoluted bore PTFE braided hoses offer improved flexibility and kink resistance.

Are there color options available for PTFE braided hose?

We can offer PTFE braided tubing with different color options for the outer braiding, helping with identification or aesthetic preferences.

Do you have stock samples? And how to get them?

Yes, we have a large inventory of PTFE braided hoses in our warehouse, sample orders are free and only take 5~7 days leading time for a quick quality check.

What is the shelf life of your PTFE braided hose?

The shelf life of our PTFE braided hose depends on storage conditions. When stored properly in a dry and cool environment, it can have a very long shelf life.

What if your PTFE braided hoses has quality issues after we receive them?

We will follow the below steps to solve the quality issues that may occur.

- Customers take photos of unqualified goods and then our sales staff will send them to the Quality Department to verify.

- If the issue is confirmed, our sales staff will explain the root cause and take corrective actions in the coming orders.

- Finally, we will negotiate with our customers to make some compensation.

What are your payment terms?

- For sample orders, Paypal or T/T 100% as a deposit.

- For bulk orders, we request 30% by T/T in advance, the balance to be paid before shipment.