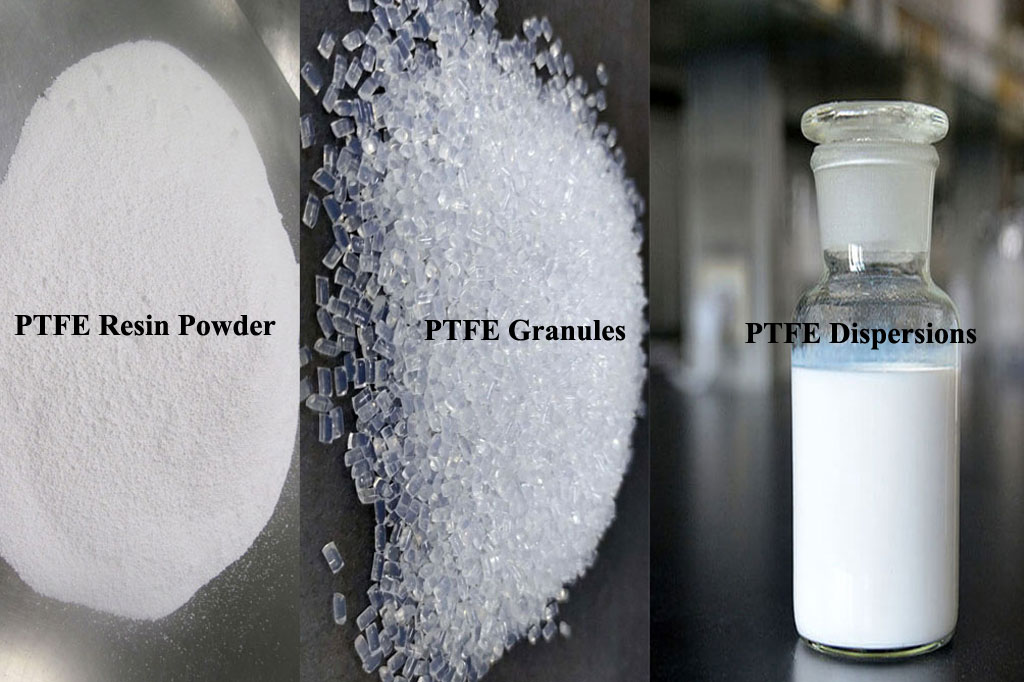

When it comes to manufacturing PTFE products, there are three main raw material forms to consider: PTFE resin powder, PTFE granules, and PTFE dispersions. Each form has its own advantages and applications.

In this article, we will compare these three PTFE raw materials in terms of their properties, processing methods, and applications.

Property | PTFE Resin Powder | PTFE Granules | PTFE Dispersions |

Form | Fine powder | Coarse powder | Liquid dispersion |

Particle Size | Micron-sized | Granule form | Sub-micron-sized |

Solids Content | 100% | 100% | 20% - 60% |

Processing Method | Compression molding, ram extrusion, paste extrusion, etc. | Compression molding, ram extrusion, paste extrusion, etc. | Coating, impregnation, spraying, etc. |

Applications | Seals, gaskets, bearings, electrical insulation, lubrication, etc. | Sheets, rods, tubes, films, moldings, etc. | Coatings, impregnation, lubrication, additives in paints and coatings, etc. |

Curing | Require sintering | Require sintering | Not require sintering |

UV Resistance | Poor | Good | Excellent |

For more details, please keep reading…

PTFE Resin Powder

PTFE resin powder is the most common form of PTFE raw material. It is a white, fine powder with excellent flow properties. PTFE resin powder is produced by the polymerization of tetrafluoroethylene gas and subsequent grinding and classification processes. It has a high molecular weight and is characterized by its uniform particle size distribution. Due to its fine particle size, PTFE resin powder is suitable for applications that require thin films, coatings, or paste extrusion.

PTFE Granules

PTFE granules are produced by the suspension polymerization of tetrafluoroethylene. Unlike PTFE resin powder, PTFE granules have larger particle sizes and irregular shapes. They are commonly used in compression molding, ram extrusion, and paste extrusion processes. PTFE granules offer excellent moldability and are ideal for manufacturing complex shapes, such as PTFE rods, PTFE tubes, PTFE sheets, and PTFE gaskets. They are also used for compression molding of intricate components, such as PTFE seals and O-rings.

PTFE Dispersions

PTFE dispersions consist of fine PTFE particles suspended in water or an organic solvent. They are produced by emulsion polymerization or dispersion processes. PTFE dispersions are primarily used for coating applications, such as non-stick coatings for cookware, industrial coatings for equipment, and fabric coatings for waterproofing. They can be applied through spraying, dipping, brushing, or roll-coating methods. PTFE dispersions offer excellent adhesion and create a smooth, low-friction surface.

Properties Comparison

Now, let’s compare these three PTFE raw materials based on specific properties:

- Processability: PTFE resin powder and PTFE granules can be processed using compression molding, ram extrusion, or paste extrusion techniques. PTFE dispersions, on the other hand, require coating processes.

- Particle Size: PTFE resin powder has the smallest particle size, followed by PTFE dispersions, and PTFE granules have the largest particle size. The particle size affects the material’s flowability, moldability, and surface finish.

- Application Range: PTFE resin powder is suitable for applications requiring thin films, coatings, or paste extrusion. PTFE granules are ideal for compression molding and extrusion processes, enabling the production of complex shapes. PTFE dispersions are primarily used for coating applications.

- Cost Considerations: PTFE resin powder is typically more expensive than PTFE granules and dispersions due to the additional processing steps involved.

In Conclusion

PTFE resin powder is suitable for thin films, coatings, and paste extrusion. PTFE granules offer excellent moldability and are ideal for compression molding and extrusion processes. PTFE dispersions are used for coating applications. Understanding the properties and applications of these raw materials is essential for selecting the most suitable form of PTFE for a specific manufacturing process or end-use application.

Dear Sir / Madam,

My name is Fabio Cypukova and I am a material engineer at an Israeli producer of cables.

I am interested in more information about the use of fluoropolymers in electrical and data transfer cables, would you have more information about this?

PTFE in pellet form can be processed in a single screw extruder L/D 24 or 30?

Warm regards,