PTFE heat shrink tubing is commonly used in industries such as aerospace, automotive, electronics, telecommunications, and medical devices. Typical applications include insulation and protection of wiring harnesses, connectors, sensors, probes, and other delicate components where high-temperature resistance and chemical resistance are required.

Here are some key features and benefits of PTFE heat shrink tubing:

- High and low temperature resistance -200~180°C.

- Excellent electrical insulation performance, extremely high resistance, and a dielectric constant of about 2.0 (the smallest among all electrical insulating materials).

- Excellent anti-oxidation performance, can be used outdoors for a long time.

- High transparency, the lowest light refractive index among all plastics.

- It can be reprocessed, self-sealing and welded.

PTFE Heat Shrink Tubing Tests

To ensure the quality and reliability of our PTFE heat shrink tubing, it is subjected to various ASTM (American Society for Testing and Materials) tests to check its physical, mechanical, thermal, and electrical properties.

Property | Test Method | Value |

Density (g/cm3) | ASTM D792 | 2.15 |

Melting point (°C) | 260 | |

Shrink rate (%) | 3.5~4.0 | |

Hardness | Shore D | D55 |

Elongation at break (%) | ASTM D638 | 250~330 |

Tensile strength (Mpa) | ASTM D638 | 19~35 |

Bending strength (Mpa) | ASTM D790 | not broken |

Compressive strength (Mpa) | ASTM D695 | 17 |

Tensile modulus of elasticity (Mpa) | ASTM D638 | 345 |

Coefficient of friction | Compared to steel | 0.05 |

Processing temperature (°C) | 300~400 | |

Decomposition temperature (°C) | >400 | |

Maximum continuous working temperature (°C) | 20000h | -85~200 |

Heat distortion temperature (°C) | 1.8ZMpa | 50 |

Coefficient of linear expansion | ASTM D696 | 8.3~10.5 |

Embrittlement temperature (°C) | -90 | |

Dielectric constant | ASTM D150, 103Hz | 2.1 |

Volume resistivity | ASTM D257 | >1018 |

Surface resistivity | ASTM D257, 25°C | >1017 |

Dielectric loss tangent | 106Hz | <0.0005 |

Resistant to chemical solvents | excellent | |

Water absorption (%) | 24h | <0.01 |

Refractive index | 1.338 | |

Limiting oxygen index | >95 |

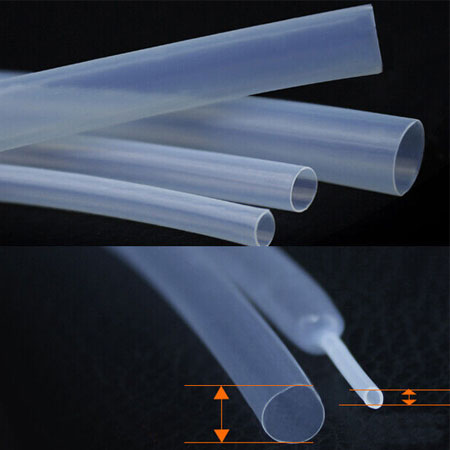

Types of Shrink Ratios

The shrink ratio of our PTFE heat shrink tubing can vary depending on the specific application and manufacturer. It is typically around 1.3:1 to 4:1. We can also produce PTFE tubing with custom shrink ratios based on your needs, consult us for its availability and feasibility now.

1.7:1 Shrink Ratio

It provides a moderate amount of shrinkage and is suitable for applications where a slight reduction in diameter is required. It may offer good flexibility and ease of installation due to its lower shrink ratio.

2:1 Shrink Ratio

It provides a more significant reduction in diameter compared to 1.7:1. It is commonly used for insulation, strain relief, and protecting small components or wires. It offers a balance between flexibility and shrinkage.

4:1 Shrink Ratio

It is suitable for applications where a substantial reduction in diameter is required, such as encapsulating connectors or splices. It offers better strain relief and sealing properties compared to lower shrink ratios.