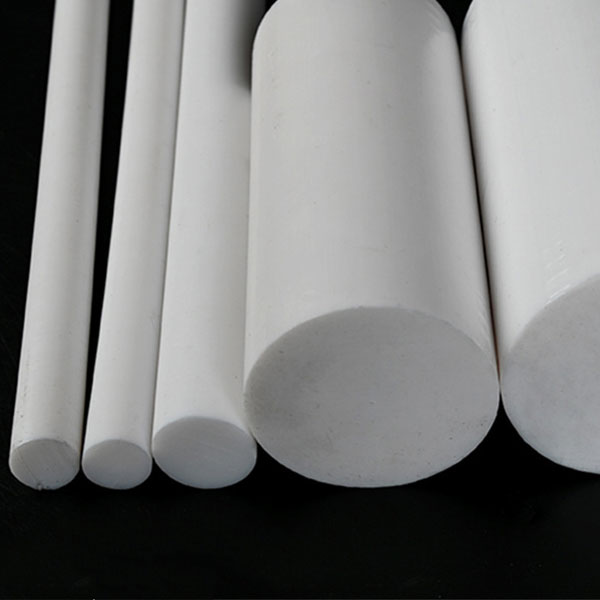

PTFE Rod

PTFE Rod is mainly suitable for the manufacture of long-sized products and non-standard components.

PTFE Solid Rod

PTFE solid rods have a uniform cross-section throughout. They offer excellent strength and rigidity due to their compact structure. They can withstand bending, twisting, and compression forces without deformation. They can be machined into custom parts, such as bearings, seals, gaskets, valve components, insulators, and structural supports.

PTFE Hollow Rod

PTFE hollow rods are available in different wall thicknesses, outer diameters, and lengths. They are lighter and more flexible compared to solid rods due to the absence of material in the central cavity. They are often used in applications where weight reduction is important or where the passage of fluids, wires, or other components through the center is required.

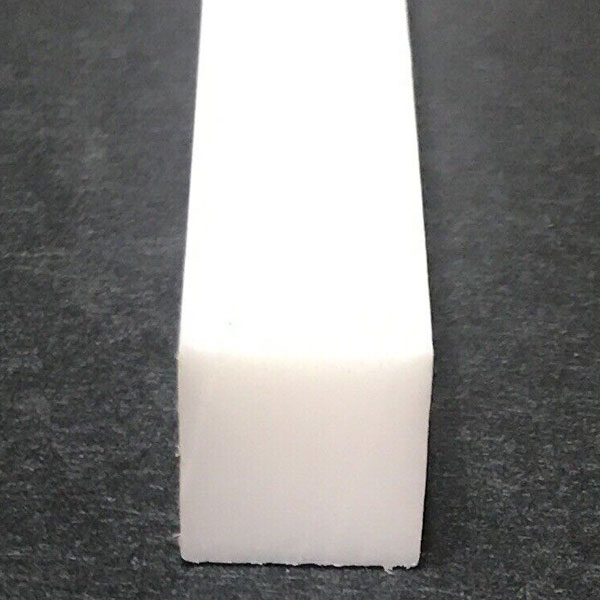

PTFE Bar

PTFE round bars, square bars, and rectangle bars are all variations of PTFE bars made from the same material but differ in their shape. Round bars are often preferred for their ease of machining and rotational properties. Square bars offer improved gripping and stability, while rectangle bars provide structural strength with varying width and thickness options.

PTFE Round Bar

A PTFE round bar is cylindrical in shape and has a uniform diameter throughout its length. It is often used in applications where rotational or symmetrical properties are required. They are also suitable for machining into custom components (such as seals, gaskets, bearings, and insulators) due to their symmetrical shape.

PTFE Square Bar

A PTFE square bar has a square cross-section with equal sides. It offers more surface area and increased stability and resistance to twisting compared to round bars. They are often used in applications where rigidity and dimensional stability are important, such as in structural components, supports, and guides.

PTFE Rectangular Bar

A PTFE rectangle bar has a rectangular cross-section with varying width and thickness dimensions. Compared to round and square bar, it is more suitable for applications requiring structural strength, a specific width-to-thickness ratio or a larger contact area, such as in wear strips, slide bearings, and electrical insulation.

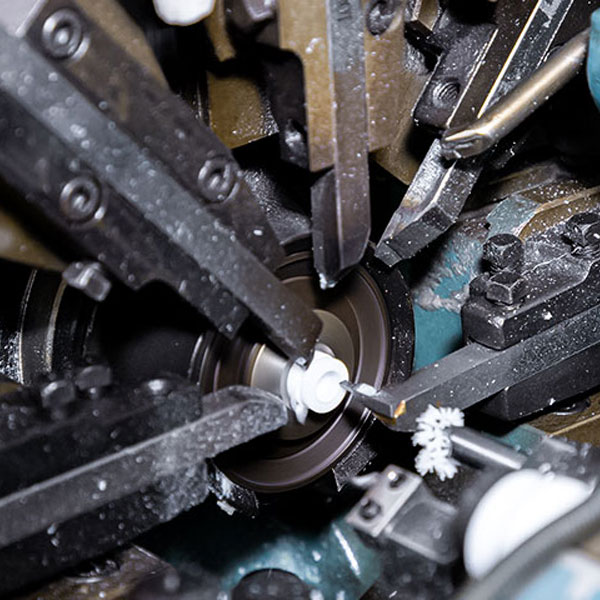

Production Methods

Our PTFE rod production involves two primary methods: molding and extrusion. Molding allows for precise control over the dimensions and properties, while extrusion is often used for continuous production of longer lengths.

Molded PTFE Rod

In this method, PTFE powder is compressed and heated inside a mold. The heat causes the PTFE particles to fuse together, resulting in a solid rod shape. Molded rods are typically produced in a specific length and diameter (dia 6 mm~300 mm, length 100 mm~300 mm) according to the mold. This method allows for the creation of short PTFE rods with precise dimensions and high-quality surface finish.

Extruded PTFE Rod

In this process, PTFE resin is forced through a die under high pressure and temperature. The resin is pushed through the die, resulting in a continuous, cylindrical shape. The extruded rod is then cooled and cut to the desired size (dia 4 mm~200 mm, length 500 mm~3000 mm). Extrusion is a cost-effective method for producing long PTFE rods in large quantities and can accommodate various diameters.

Filled PTFE Rods

The addition of fillers to PTFE can enhance specific properties and expand its range of applications.

Glass Filled PTFE Rod

These rods are reinforced with glass fibers (ranging from 5% to 40% by weight), which increase the mechanical strength and dimensional stability and offer improved tensile strength, flexural strength, and resistance.

Carbon Filled PTFE Rod

Carbon is added as a filler to improve the electrical conductivity. These rods find applications in industries such as electronics, where static dissipation or electrical conductivity is required along with PTFE's other desirable properties.

Bronze Filled PTFE Rod

Bronze powder is added to PTFE to improve its mechanical strength, wear resistance, and dimensional stability. Bronze filled PTFE rods are commonly used in applications involving high-speed and high-pressure conditions.

Get In Touch With Us

FAQs of PTFE Rod

What are your available dimensions of PTFE rods?

Our PTFE rods come in various sizes and dimensions, ranging from small diameters (e.g., 3mm) to larger diameters (e.g., 100mm), and varying lengths, such as 1m, 2m, or customized.

Do the PTFE hollow rods need to customize?

Our PTFE hollow rod can be customized according to the size provided by the customers, and we also have some common size in stock.

Can you supply square and rectangular PTFE bars?

Yes, our PTFE bar have some common size in stock, also we can cut into ordered size from PTFE plate.

Do you have stock samples? And how to get it?

Yes, we have a large inventory of different PTFE rods and bars in our warehouse, free sample orders are available for quality check, and the lead time is 5-7 days.

What are your payment terms?

- For sample orders, Paypal or T/T 100% as a deposit.

- For bulk orders, we request 30% by T/T in advance, the balance to be paid before shipment.